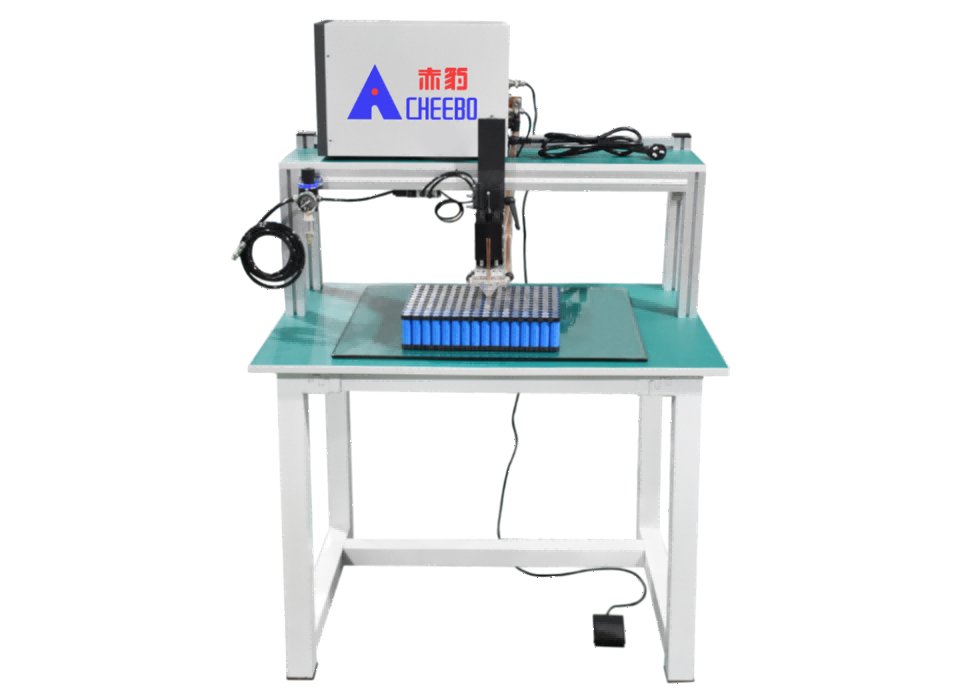

How to choose a gantry spot welding machine

2024-03-30 18:45:00

When choosing a gantry spot welding machine, the following key factors need to be considered:

1. Welding requirements: First, you need to determine your welding requirements, including welding materials, size and shape of the welded workpiece, production volume, etc. This helps determine the required welding machine type and specifications.

2. Welding parameters: Select a gantry spot welding machine with appropriate welding parameter range according to the requirements of the welding process, including welding current range, welding time range, pressure range, etc.

3. Welding head design: Consider the design of the required welding head to ensure it is suitable for your welding workpiece. Some gantry spot welding machines are equipped with replaceable welding heads, which can increase their flexibility.

4. Automation level: Consider choosing manual, semi-automatic, or fully automatic gantry spot welding machines based on production needs and budget. Fully automated equipment typically has higher production efficiency and consistency, but also higher costs.

5. Welding space and workbench size: Ensure that the selected gantry spot welding machine has sufficient welding space and an appropriately sized workbench to accommodate your welded workpiece.

6. Brand and Quality: Choose well-known brands of gantry spot welding machines, which usually have higher quality and reliability. At the same time, consider the manufacturing materials, processes, and quality control standards of the equipment.

7. After sales service and support: Ensure that the selected supplier can provide timely after-sales service and support, including equipment installation and commissioning, training, maintenance, and spare parts supply.

8. Cost considerations: Finally, based on budget and performance requirements, choose a cost-effective gantry spot welding machine, while considering the long-term investment return rate of the equipment.

In summary, selecting a suitable gantry spot welding machine requires comprehensive consideration of welding requirements, welding parameters, welding head design, automation level, space dimensions, brand quality, after-sales service, and cost.

Previous:Can gantry spot welding machine weld irregular shaped batteries? Next:Introduction to the principle of lithium battery spot welding machine by battery module pack production line manufacturer

You Can Also Search For Relevant Information Tags:

【Recommended Reading】

Service Hotline

Service Hotline

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry