Battery Automation Equipment Exhibition Hall

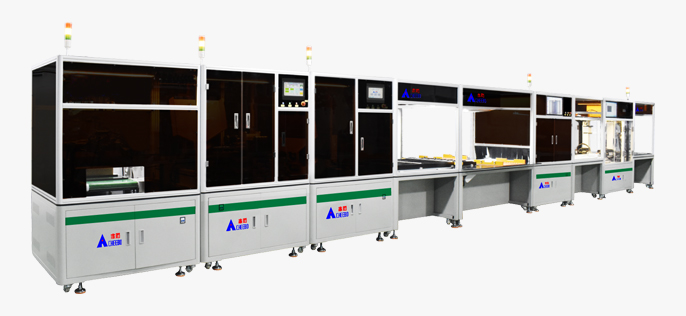

The Device Is Suitable For Various Types Of Battery Pack ModulesBattery Pack Automatic Production Line

18650, 21700, 26650, 26700, 32650, 32700, 22650 And Other Models Of Lithium Batteries Are Fully CompatibleEach Device In The Production Line Can Operate Independently, And Even If A Single Device Fails, The Overall Process Of The Production Line Is Not Affected Learn More

Battery Welding Machine

135 ° Rotating Welding Head Single-Sided/Double-Sided Battery Spot Welding Machine ± 0.1mm High-Precision Electric/Pneumatic Gantry Spot Welding MachinePrecision Welding Machine Head Independently Developed, With Consistent Welding Points And Precise Adjustable Welding Pressure Learn More

CHEEBO Technology · Core Technical Competencies

Prioritize Quality, Provide Excellent Service, And Offer One-Stop Support For Research And Development Production01.

High Precision Control Technology

- Most Of The Core Components Of The Equipment Are From Internationally Renowned Brands Such As Mitsubishi Plc And Taiwan Hiwin Rail

- Imported Raw Materials Such As Panasonic Servo Motors

- Improve Equipment Accuracy From The Source To Ensure Product Quality

02.

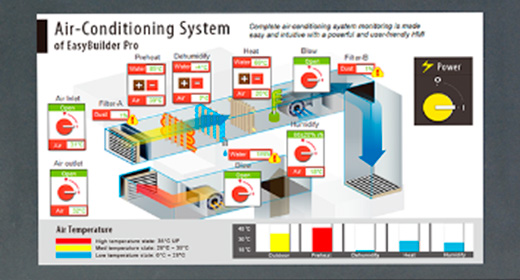

Intelligent Monitoring System

- Zero Misjudgment Of Ccd Detection And Pressure Tracking System

- Functions Such As Automatic Alarm For Explosion Welding And Virtual Welding

- Real Time Monitoring Of Welding Quality To Achieve High-Quality Control At Every Stage

03.

Data Analysis And Optimization Techniques

- Battery Pack Tracking System, Industrial Computer Welding Path Real-Time Display System, Mes Production Statistics System, Etc

- Real Time Collection And Analysis Of Production Data

- Resolve Potential Production Issues And Improve Production Efficiency

04.

Modular Design Technology

- Quickly Replace And Upgrade Various Equipment Modules According To Different Production Needs

- Reduce Equipment Maintenance Costs And Meet Non-Standard Personalized Needs

CHEEBO Technology · Product Applications

The Device Is Widely Used In Multiple Scenarios Transportation Vehicle Field

Transportation Vehicle Field 3C Digital Field

3C Digital Field Industrial And Commercial Energy Storage Field

Industrial And Commercial Energy Storage Field Household Electric Tools

Household Electric Tools Industrial Handling Field

Industrial Handling Field Landscape Tool Field

Landscape Tool Field In The Field Of Household Appliances

In The Field Of Household AppliancesLifetime Maintenance Of Equipment, 8 Reasons To Choose Us

CHEEBO Technology · Enterprise AdvantagesFree Technical Support

Technical Support

1-Year Warranty

3-5 Days Delivery

5 Years Of Service

Free On-Site Service

Famous Raw Materials From Taiwan And Japan

Adopting Well-Known Domestic And Foreign Brands

100% Full Inspection For Shipment

Sufficient Stock

1H Response Mechanism

3-5 Hour On-Site Service Within The Province

CHEEBO Technology · Company Profile

Large Quantity Of Spot Goods, Supporting CustomizationHigh Precision Cylindrical Battery

Automation Equipment Research And Development Manufacturer

A Technology-Based High-Tech Enterprise That Integrates Research And Development, Production, Sales, And Service. Engaged In The Research And Development Of Lithium Battery Assembly Equipment With 25

Over The Years, We Have Focused On Product Quality Research And Development.

1000+Tower

Annual Production And Delivery Of Equipment25Year

R&D And Production Experience3000㎡

Industrial Plant50+Term

Research And Development ProjectsCHEEBO Technology · Customer Witness

Successfully Served Thousands Of Pack Factories

CHEEBO Technology · Brand Raw Material Supplier

Choose World-Class Materials And Create Competitive ProductsCHEEBO Technology · Research Institute

Follow The Updates Of CHEEBO And Stay Up-To-Date With The Latest News Maintenance of lithiu...

Maintenance of lithiu...

Lithium battery spot welding machines play an important role in lithium battery produ...

How to choose a sui...

How to choose a sui...

The selection of spot welding machines is crucial in various stages of lithium batte...

Innovative technology...

Innovative technology...

Against the backdrop of global energy structure transformation and increasing environme...

Service Hotline

Service Hotline

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry