> Customer Witness >

> Customer Witness > Project Log

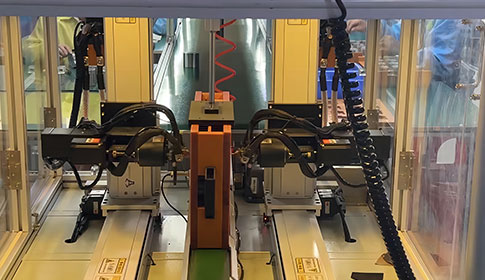

8-Axis Fully Automatic Battery Spot Welding Machine Achieves High-Quality And Efficient Production For Customers

- Collaboration Time:2021/7

- Customer Demand:The battery pack and nickel sheet have irregular shapes, high welding failure rate, and low manual welding efficiency

- Delivery Highlights:8-axis fully automatic spot welding machine, with a 135 ° rotating welding head that can set the welding angle according to requirements, suitable for welding various irregular nickel sheets. The equipment has a welding defect alarm function. Fundamentall

- Delivery Cycle:3 days

Overview of Cooperation

In July 2021, at the Guangzhou New Energy Exhibition, we met Mr. Wang from the engineering department of the company, who raised the problems they were currently facing on site and consulted our engineers for solutions. We had a brief communication at the exhibition and learned about our equipment. After the exhibition, our business personnel and engineers visited the company with welding samples. The company's engineering department evaluated the welding effect of the welding samples on site and finally reached a cooperation agreement.

Equipment solutions provided by Cheebo Technology

Equipment features

1. The independently developed electric precision rotary welding head can rotate 135 ° for welding, suitable for various shaped nickel sheets, and has anti sticking needle function.2. The left and right platforms can be operated independently, and welding paths can be set independently according to different welding requirements.

3. Explosion welding and virtual welding equipment automatically alarm, manual adjustment of automatic area welding repair, single point welding repair.

4. Using Taiwan's silver wire rod guide module, it has high precision, low noise, smooth sliding, and durability.

5. High definition LCD touch screen, interactive human-machine interface with simple and convenient operation.

6. Manual programming, CAD mapping, importing spot welding paths, and quickly implementing programming. Easy to learn, ordinary workers can set it up.

7. Energy switching function, capable of storing 4 sets of energy modes, automatically switching between different welding energies for different materials.

8. Production counting function, set production quantity, and automatically stop production to achieve output.

9. Welding needle compensation function, set the number of welding needles, and automatically remind to perform welding needle maintenance after reaching the number of times.

10. The debugging function allows for fine-tuning of the welding head and saving of spot welding parameters for each point (facilitating the modification of the coordinates of the welding points), as well as adjustment using the one click calibration function.

11. Adopting a through type design structure (capable of both forward and backward movement), it can be connected to the production line for continuous use. After welding, it can be removed from the assembly line side.

12. Aluminum alloy skeleton, imported acrylic protective plate, beautiful and elegant, strong sense of technology, visual operation improves production safety factor.

Content That You May Be Interested In

Service Hotline

Service Hotline

E-mail:Cheebo@126.com

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry

Copyright © 2019 Shenzhen Cheebo Technology Co., Ltd All Rights Reserved. 粤ICP备19046161号

Website MapTechnical Support:SysxWeb