--Home--Academy--Company News-- Technological breakthrough and application prospects of fully automatic lithium battery spot welding machine

--Home--Academy--Company News-- Technological breakthrough and application prospects of fully automatic lithium battery spot welding machineTechnological breakthrough and application prospects of fully automatic lithium battery spot welding machine

2024-05-16 10:28:09

With the rapid development of electric vehicles and renewable energy industries, lithium batteries, as one of their key components, have increasingly become a focus of attention on the automation level of their production lines. In this context, the technological breakthrough and application prospects of fully automatic lithium battery spot welding machines have attracted much attention. This article will explore the technological breakthroughs and application prospects of fully automatic lithium battery spot welding machines in achieving production automation.

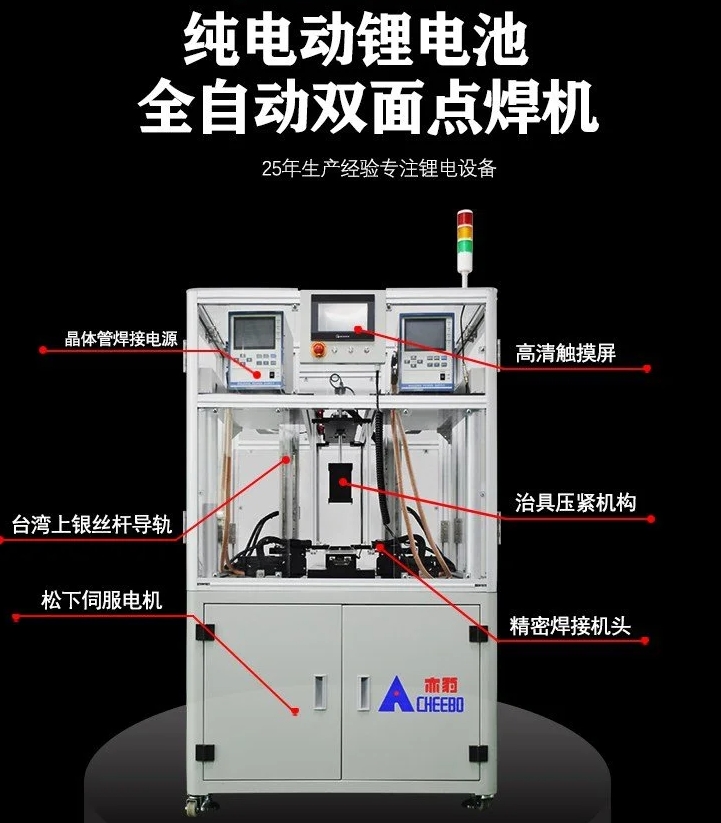

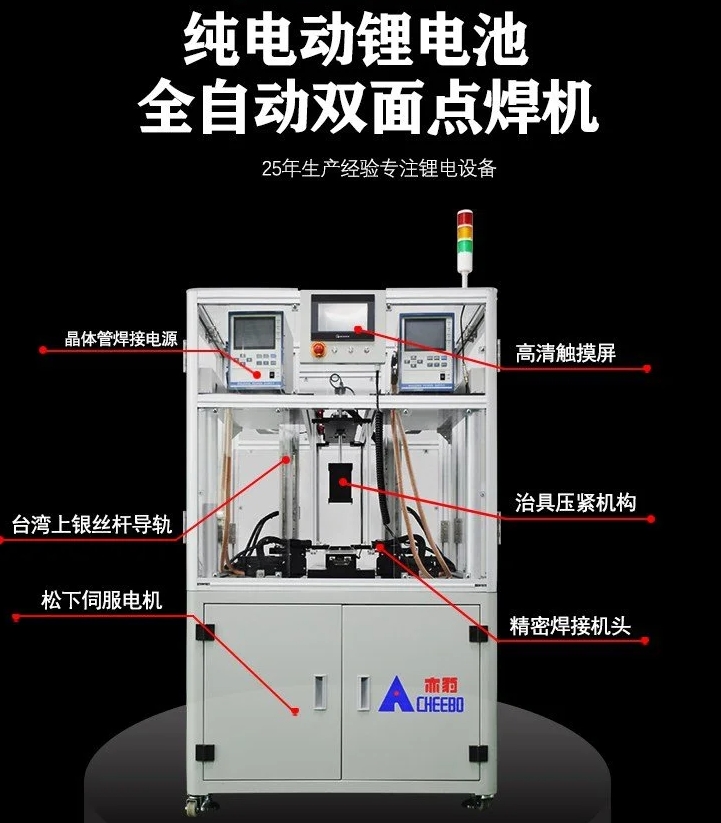

Firstly, let's take a look at the technological breakthrough of the fully automatic lithium battery spot welding machine. Compared to traditional semi-automatic or manual spot welding machines, fully automatic lithium battery spot welding machines have a higher degree of automation and intelligence. The key technological breakthroughs are mainly reflected in the following aspects: firstly, the upgrade of the automation control system. The fully automatic lithium battery spot welding machine is equipped with advanced control systems and sensors, which can achieve full automation control, including battery cell clamping, welding parameter adjustment, welding process monitoring, etc., greatly improving welding efficiency and stability. The second is the application of intelligent welding technology. The fully automatic lithium battery spot welding machine can automatically adjust the welding parameters based on the size, shape, and material parameters of the battery cells to achieve the best welding effect. At the same time, it can automatically identify and handle abnormal situations during the welding process, improving the stability and reliability of the production line. The third is the optimization of human-computer interaction interface. The fully automatic lithium battery spot welding machine adopts an intuitive and friendly human-computer interaction interface, which is easy to operate and can achieve remote monitoring and operation, improving the flexibility and management efficiency of the production line.

Secondly, let"s look forward to the development of fully automatic lithium battery spot welding machines in terms of application prospects. With the continuous growth of the electric vehicle and renewable energy markets, the demand for lithium batteries will continue to increase, and fully automatic lithium battery spot welding machines, as the core equipment on the production line, will play an increasingly important role in the battery production process. In the future, with the continuous advancement of technology and the continuous reduction of costs, it is believed that fully automatic lithium battery spot welding machines will gradually become popular and applied to battery manufacturers of all scales, providing strong support for the healthy development of electric vehicles and renewable energy industries.

Secondly, let"s look forward to the development of fully automatic lithium battery spot welding machines in terms of application prospects. With the continuous growth of the electric vehicle and renewable energy markets, the demand for lithium batteries will continue to increase, and fully automatic lithium battery spot welding machines, as the core equipment on the production line, will play an increasingly important role in the battery production process. In the future, with the continuous advancement of technology and the continuous reduction of costs, it is believed that fully automatic lithium battery spot welding machines will gradually become popular and applied to battery manufacturers of all scales, providing strong support for the healthy development of electric vehicles and renewable energy industries.

Overall, as a key equipment for achieving production automation, the fully automatic lithium battery spot welding machine has exciting technological breakthroughs and application prospects. I believe that with the continuous development of technology and the increasing market demand, fully automatic lithium battery spot welding machines will make greater contributions to the sustainable development of electric vehicles and renewable energy industries.

Previous:Key issues and future prospects of lithium battery spot welding technology development Next:Analysis of the working principle and key technological innovation of fully automatic lithium battery spot welding machine

Firstly, let's take a look at the technological breakthrough of the fully automatic lithium battery spot welding machine. Compared to traditional semi-automatic or manual spot welding machines, fully automatic lithium battery spot welding machines have a higher degree of automation and intelligence. The key technological breakthroughs are mainly reflected in the following aspects: firstly, the upgrade of the automation control system. The fully automatic lithium battery spot welding machine is equipped with advanced control systems and sensors, which can achieve full automation control, including battery cell clamping, welding parameter adjustment, welding process monitoring, etc., greatly improving welding efficiency and stability. The second is the application of intelligent welding technology. The fully automatic lithium battery spot welding machine can automatically adjust the welding parameters based on the size, shape, and material parameters of the battery cells to achieve the best welding effect. At the same time, it can automatically identify and handle abnormal situations during the welding process, improving the stability and reliability of the production line. The third is the optimization of human-computer interaction interface. The fully automatic lithium battery spot welding machine adopts an intuitive and friendly human-computer interaction interface, which is easy to operate and can achieve remote monitoring and operation, improving the flexibility and management efficiency of the production line.

Overall, as a key equipment for achieving production automation, the fully automatic lithium battery spot welding machine has exciting technological breakthroughs and application prospects. I believe that with the continuous development of technology and the increasing market demand, fully automatic lithium battery spot welding machines will make greater contributions to the sustainable development of electric vehicles and renewable energy industries.

Previous:Key issues and future prospects of lithium battery spot welding technology development Next:Analysis of the working principle and key technological innovation of fully automatic lithium battery spot welding machine

You Can Also Search For Relevant Information Tags:

【Recommended Reading】

- 2024-11-06Introduction to the production process of battery module pack production line

- 2024-11-06What equipment is included in the battery module pack production line

- 2024-11-06Maintenance and upkeep of lithium battery spot welding machine

- 2024-11-06Working principle of lithium battery spot welding machine

Service Hotline

Service Hotline

E-mail:Cheebo@126.com

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry

Copyright © 2019 Shenzhen Cheebo Technology Co., Ltd All Rights Reserved. 粤ICP备19046161号

Website MapTechnical Support:SysxWeb