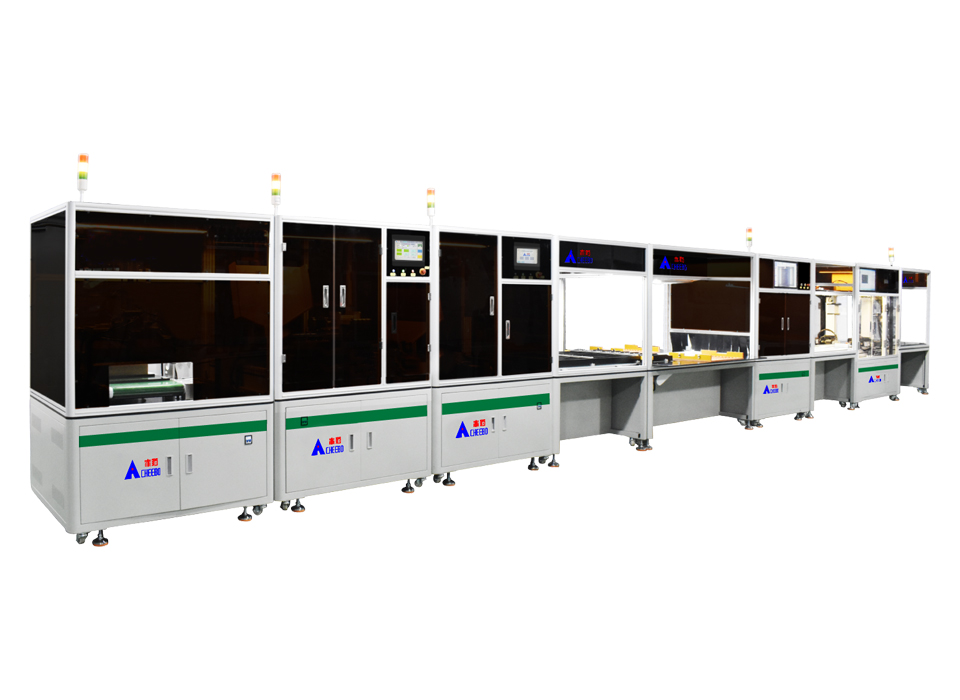

Double Sided Battery Spot Welding Machine Pack Automatic Production Line

Product Feature Description:

1、Suitable For Assembling Most Cylindrical Battery Packs Of 18650/21700/26650/26700/32700, With Strong Compatibility。

2、The Entire Line Includes Loading, Labeling, Sorting, Spot Welding, And One-Stop Assembly, Which Can Effectively Improve Production Efficiency。

3、Only 3-4 People Are Needed To Complete The Front-End Assembly Of The Battery Pack On The Entire Line, Which Can Effectively Save Labor Costs。

4、The Entire Line Is Assembled Using Single Machine Equipment And Can Be Used Independently。

Standard Equipment Procurement

Equipment Customization And Upgrade Consultation

2、The Entire Line Includes Loading, Labeling, Sorting, Spot Welding, And One-Stop Assembly, Which Can Effectively Improve Production Efficiency。

3、Only 3-4 People Are Needed To Complete The Front-End Assembly Of The Battery Pack On The Entire Line, Which Can Effectively Save Labor Costs。

4、The Entire Line Is Assembled Using Single Machine Equipment And Can Be Used Independently。

24H Service Hotline:19928807536

Main Features Of The Product

1、Suitable For Battery Cells: Overall Suitable For 18650 18700 21650 21700 26650 32650 32700 Cylindrical Steel Shell Battery Cells (Ccd And Double-Sided 8-Axis Automatic Spot Welding Machine Parts Can Also Be Used For 33140 Adaptive Resistance Welding Battery Cells)。

2、Whole Box Loading Of Battery Cells Is Labor-Saving And Time-Saving。

3、Integrated Design Of Production Line Body, Forward Design Of Battery Cell Feeding Mechanism, Easy Operation, Overall Beautiful Appearance。

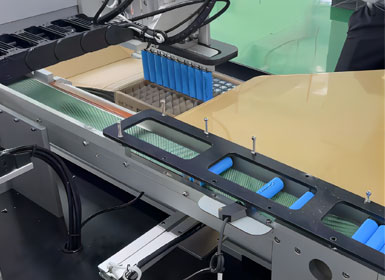

4、Sorting The Battery Cells And Discharging Them Directly To The Hands Of The Discharge Cell Operators Saves Manpower And Time。

5、Manual Installation Of Battery Cell Workbench And Integrated Design Of Wire Body For Easy Operation。

6、CCD Automatic Front And Rear Sensing For Entry And Exit Work, Fully Automatic Without Human Intervention During Normal Operation, And Manual Handling When Product Abnormalities Are Detected。

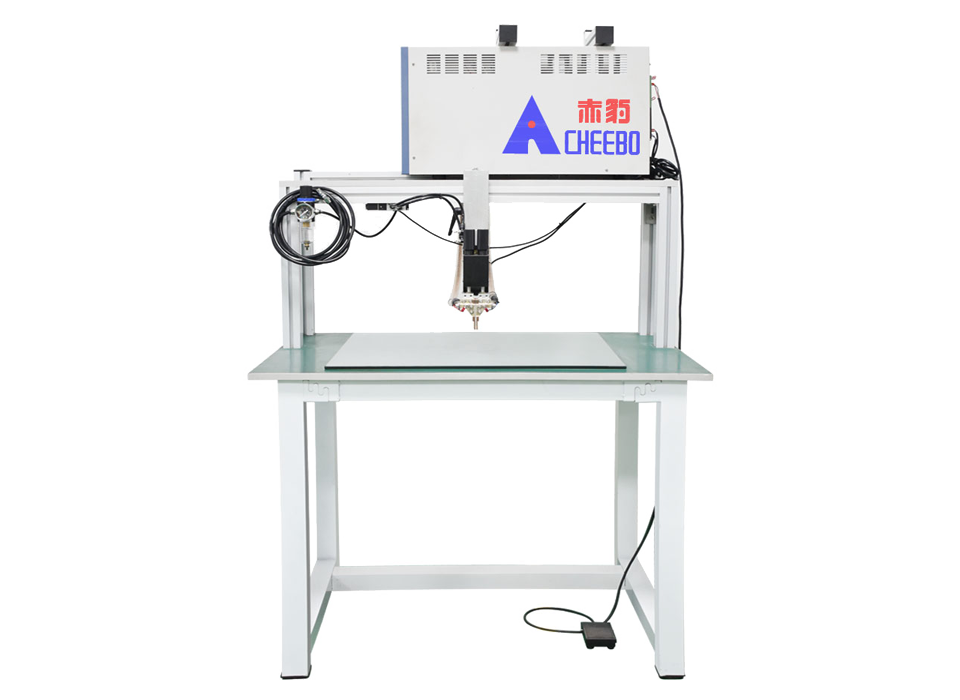

7、Eight Axis Double-Sided Automatic Spot Welding Machine Can Spot Weld Slotted Battery Cells In Different Directions。

8、The Spot Welding Machine Is Placed At The Head Of The Production Line Belt Line, Making The Head Of The Production Line And Connecting The Production Line To The Assembly Line Into One。

9、Fluent Fixture Reflux Mechanism Design, Easy To Operate And Use, Does Not Occupy Space。

2、Whole Box Loading Of Battery Cells Is Labor-Saving And Time-Saving。

3、Integrated Design Of Production Line Body, Forward Design Of Battery Cell Feeding Mechanism, Easy Operation, Overall Beautiful Appearance。

4、Sorting The Battery Cells And Discharging Them Directly To The Hands Of The Discharge Cell Operators Saves Manpower And Time。

5、Manual Installation Of Battery Cell Workbench And Integrated Design Of Wire Body For Easy Operation。

6、CCD Automatic Front And Rear Sensing For Entry And Exit Work, Fully Automatic Without Human Intervention During Normal Operation, And Manual Handling When Product Abnormalities Are Detected。

7、Eight Axis Double-Sided Automatic Spot Welding Machine Can Spot Weld Slotted Battery Cells In Different Directions。

8、The Spot Welding Machine Is Placed At The Head Of The Production Line Belt Line, Making The Head Of The Production Line And Connecting The Production Line To The Assembly Line Into One。

9、Fluent Fixture Reflux Mechanism Design, Easy To Operate And Use, Does Not Occupy Space。

Product Technical Parameters

| Applicable Specifications | 18650/21700/26650/32650/32700 | Whole Line Production Efficiency | 3000PCS/H |

| Scan The Code Of The Battery Cell | Optional | Sorting Gear | 7th Gear |

| Welding Rotation Angle | 135° | XY Axis Welding Stroke | 500*360mm (Customizable) |

| Welding Thickness | 0.02-0.3MM | XY Axis Welding Accuracy | 0.1mm |

| CCD Pixel | 1000W | Testing Efficiency | 5 Seconds/Time |

| Internal Resistance Tester | Daily 3561/And Regular 3561a (Optional) | CCD Scope Of Testing | 500*600MM |

| Transmission Method | Belt | Sticker Specifications | 106mm (Negative Tolerance) X Thickness 0.1-4mm |

| Power Specifications | Single-Phase 220V 50/60HZ | Application Scenarios | Assembly Of Cylindrical Lithium Battery Pack |

Product Details Display

Fully Automatic Feeding Mechanism

7-Speed Sorting Machine

8-Axis Rotary Spot Welding Machine

CCD Positive And Negative Pole Detection

Service Hotline

Service Hotline

E-mail:Cheebo@126.com

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry

Copyright © 2019 Shenzhen Cheebo Technology Co., Ltd All Rights Reserved. 粤ICP备19046161号

Website MapTechnical Support:SysxWeb