Product Feature Description:

24H Service Hotline:19928807536

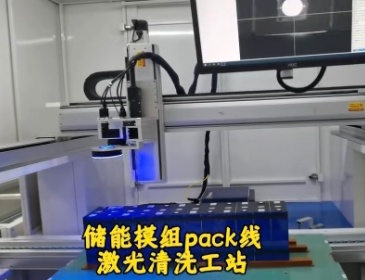

Laser welding: Primary yield ≥99.5%, secondary yield ≥ 99.9% (including rework, the yield does not include incoming material defects and defects not caused by equipment reasons)

2. The failure rate of individual equipment is ≤2%, the failure rate of the entire line equipment is ≤5%, and the designed utilization rate is ≥97%. Equipment utilization rate = (load time - downtime)/load time. Downtime not caused by equipment reasons is not included.

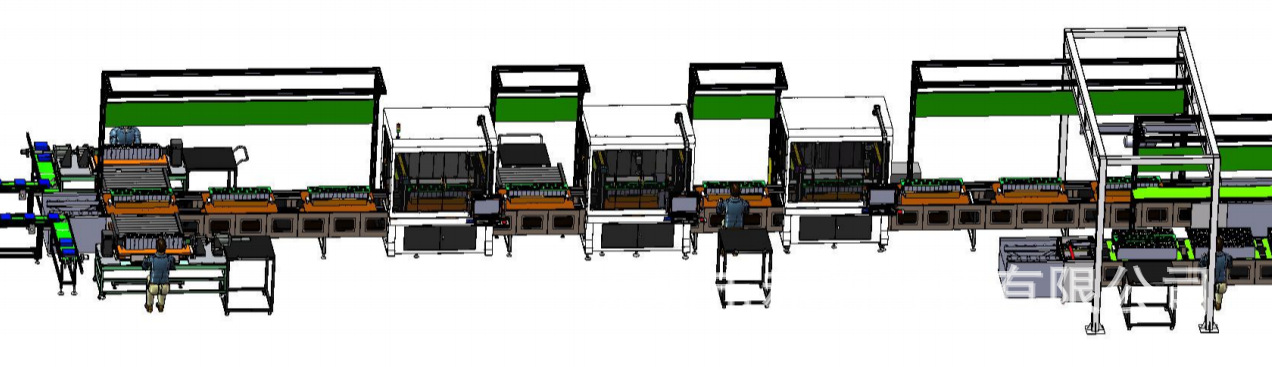

3. The total length of the entire line is approximately 34 meters, the width is 9.6 meters, and the maximum height of the equipment along the entire line is about 3.5 meters.

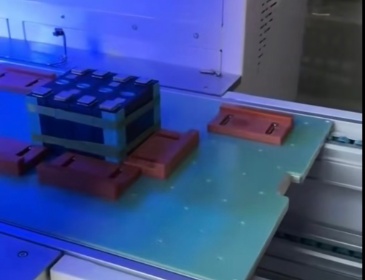

4. The entire line is divided into two major sections: module assembly section and PACK assembly section.

5. Manpower for module lines: 5 reserved manual operation positions on the line: 2 for stacking, squeezing and bundling, 1 for busbar installation, 1 for offline, and 1 for battery cell feeding and auxiliary spot checks.

6. PACK line manpower: Reserve 12 manual operation positions on the line or arrange them by yourself.

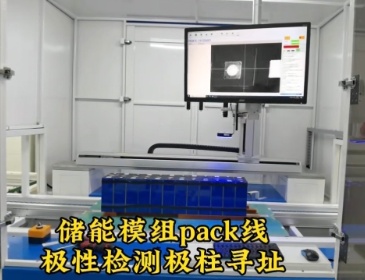

7. Production line compatibility: For modules of the same cell model, the same cell quantity, but different formulas, the pre-edited and stored programs can be called up through the central control console to achieve rapid switching in product production. For battery cell type

For modules with the same number but different numbers of battery cells, the type change can be achieved by manually adjusting the tooling fixtures at some workstations, and the type change time is ≤1 hour.

8. Equipment operation mode: The equipment is equipped with both automatic and manual adjustment modes. The parameters of the equipment's movement trajectory are adjustable. For laser welding workstations, a manual repair mode needs to be set.

| Overall line efficiency | ≥10PPM | Utilization rate | 95% |

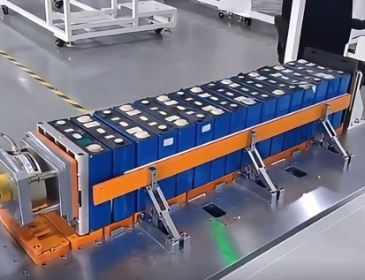

| Battery cell specification | 280(Customized) | Module specifications | 1P12S/1P13S/1P26S |

Service Hotline

Service Hotline

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry