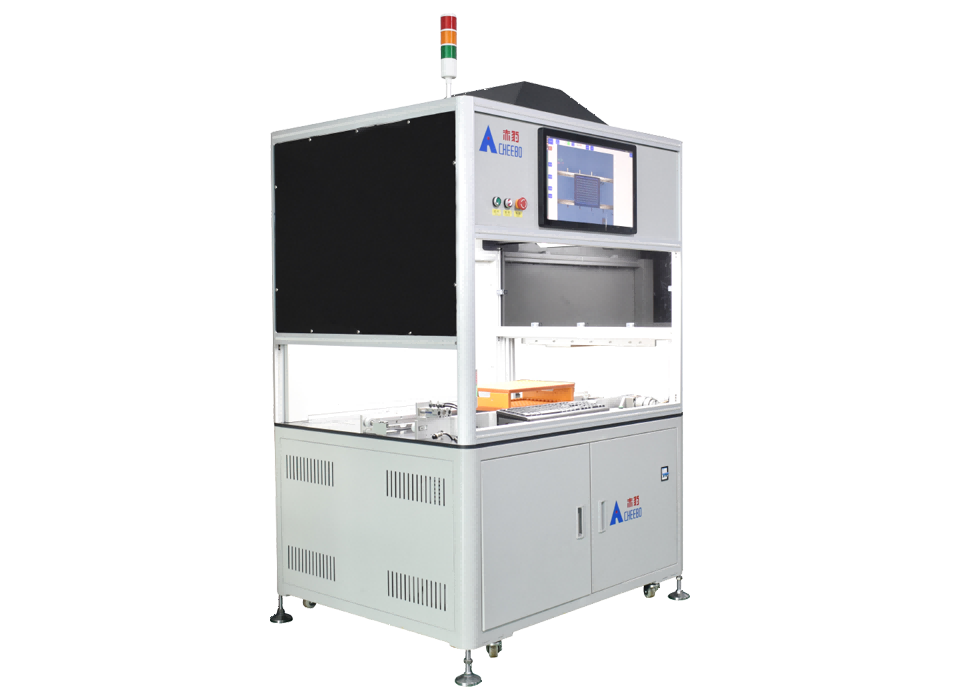

Fully Automatic Single-Sided Power Battery Spot Welding Machine CBMO4-6040

Product Feature Description:

1、Suitable For Spot Welding Processes Of Nickel Plating On Steel, Nickel Plating On Copper, And Pure Nickel Batteries。

2、Welding Cylindrical Cells Such As 18650/21700/26650/26700/32700/32140 In Series And Parallel During Battery Pack Assembly Process。

3、Using A 135 ° Rotating Welding Head For Welding, Suitable For Welding Irregular Nickel Sheets。

4、Equipment Support Function Upgrade Customization

①MES Real Time Production Statistics Of The System。

②Real Time Pressure Tracking System, Solder Joint Detection, Quality Monitoring。

Standard Equipment Procurement

Equipment Customization And Upgrade Consultation

2、Welding Cylindrical Cells Such As 18650/21700/26650/26700/32700/32140 In Series And Parallel During Battery Pack Assembly Process。

3、Using A 135 ° Rotating Welding Head For Welding, Suitable For Welding Irregular Nickel Sheets。

4、Equipment Support Function Upgrade Customization

①MES Real Time Production Statistics Of The System。

②Real Time Pressure Tracking System, Solder Joint Detection, Quality Monitoring。

24H Service Hotline:19928807536

Main Features Of The Product

1、Single Sided Automatic Welding, Modular Design That Is Silent, Stable, And Efficient。

2、The Raised Design Can Also Be Applied To The Automatic Welding Of Protective Plates For Various Pack Schemes。

3、It Can Work On Both Left And Right Platforms Without Interfering With Each Other, Or Only Use A Single Platform。

4、Using Taiwan's Silver Wire Rod Guide Module, It Has High Precision, Low Noise, Smooth Sliding, And Durability。

5、According To The Slot Position Of The Nickel Sheet, The Welding Direction Can Be Adjusted, And The Maximum Rotation Angle Of The Welding Needle Is 135 °, Effectively Avoiding Welding Errors Caused By Inability To Rotate The Angle。

6、Explosion Welding And Virtual Welding Equipment Automatically Alarm, Manual Adjustment Of Automatic Area Welding Repair, Single Point Welding Repair。

7、Manual Programming, Cad Mapping, Importing Spot Welding Paths, And Quickly Implementing Programming. Easy To Learn, Production Line Workers Can Fully Handle It。

8、High Definition Lcd Touch Screen, Interactive Human-Machine Interface With Simple And Convenient Operation。

9、Independently Develop Various Automated Intelligent Systems To Facilitate Device Operation And Help Improve Production Efficiency. Equipped With Energy Switching Function, Production Counting Function, Welding Needle Compensation Function, Manual Debugging Function, Etc。

10、Aluminum Alloy Structure, Electrostatic Powder Coating Process, Scratch Resistant, Rust Proof, Anti-Static。

11、Imported Acrylic Protective Board, Beautiful And Stylish With Strong Technological Sense, Visual Operation Improves Production Safety Factor。

2、The Raised Design Can Also Be Applied To The Automatic Welding Of Protective Plates For Various Pack Schemes。

3、It Can Work On Both Left And Right Platforms Without Interfering With Each Other, Or Only Use A Single Platform。

4、Using Taiwan's Silver Wire Rod Guide Module, It Has High Precision, Low Noise, Smooth Sliding, And Durability。

5、According To The Slot Position Of The Nickel Sheet, The Welding Direction Can Be Adjusted, And The Maximum Rotation Angle Of The Welding Needle Is 135 °, Effectively Avoiding Welding Errors Caused By Inability To Rotate The Angle。

6、Explosion Welding And Virtual Welding Equipment Automatically Alarm, Manual Adjustment Of Automatic Area Welding Repair, Single Point Welding Repair。

7、Manual Programming, Cad Mapping, Importing Spot Welding Paths, And Quickly Implementing Programming. Easy To Learn, Production Line Workers Can Fully Handle It。

8、High Definition Lcd Touch Screen, Interactive Human-Machine Interface With Simple And Convenient Operation。

9、Independently Develop Various Automated Intelligent Systems To Facilitate Device Operation And Help Improve Production Efficiency. Equipped With Energy Switching Function, Production Counting Function, Welding Needle Compensation Function, Manual Debugging Function, Etc。

10、Aluminum Alloy Structure, Electrostatic Powder Coating Process, Scratch Resistant, Rust Proof, Anti-Static。

11、Imported Acrylic Protective Board, Beautiful And Stylish With Strong Technological Sense, Visual Operation Improves Production Safety Factor。

Product Technical Parameters

| Productivity | 3600PCS/H | Welding Power Source | Multi Pulse, Transistor (Optional) |

| Welding Thickness | 0.02-0.3(Depending On The Selected Power Supply) | Cooling Method | Forced Water Circulation Cooling |

| XY Axis Welding Stroke | 600MM*400MM | Sports Style | Automatic Continuous |

| XY Axis Welding Accuracy | 0.1MM | Welding Pressure | 5KG/F (Adjustable) |

| Electrode Material | Aluminum Oxide Copper | External Dimensions | 1400*1000*1680mm |

| Power Consumption | 0.8KW During Busy Hours And 0.2KW During Idle Hours | Equipment Weight | 330KG |

| Power Specifications | Single-Phase 220V 50/60HZ 1.5KW | Application Scenarios | Large Scale Welding Of Cylindrical Batteries |

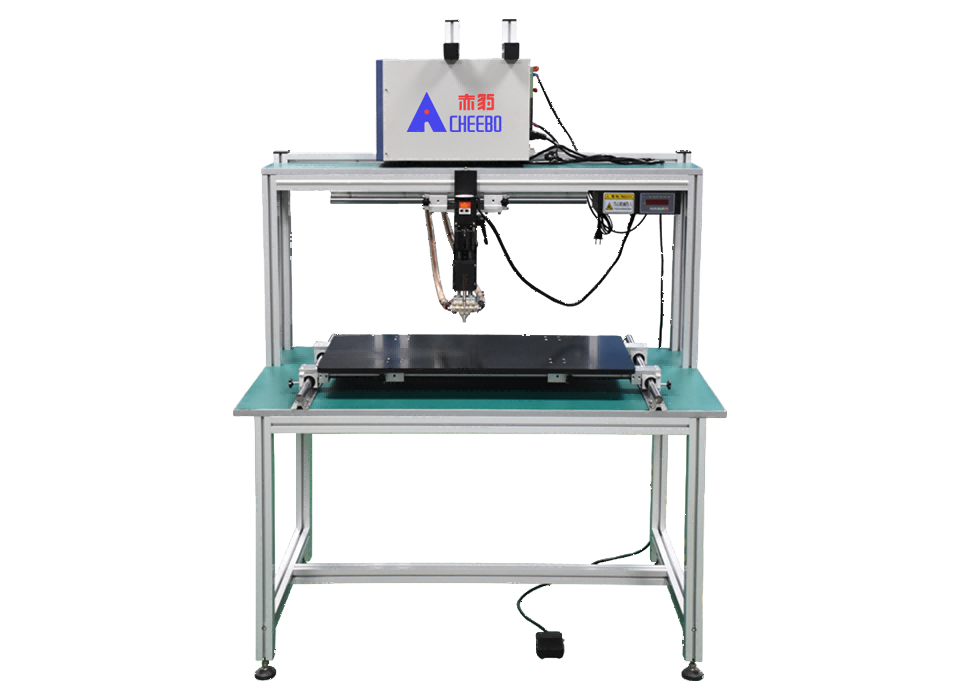

Product Details Display

Electric 135 ° Rotating Welding Head

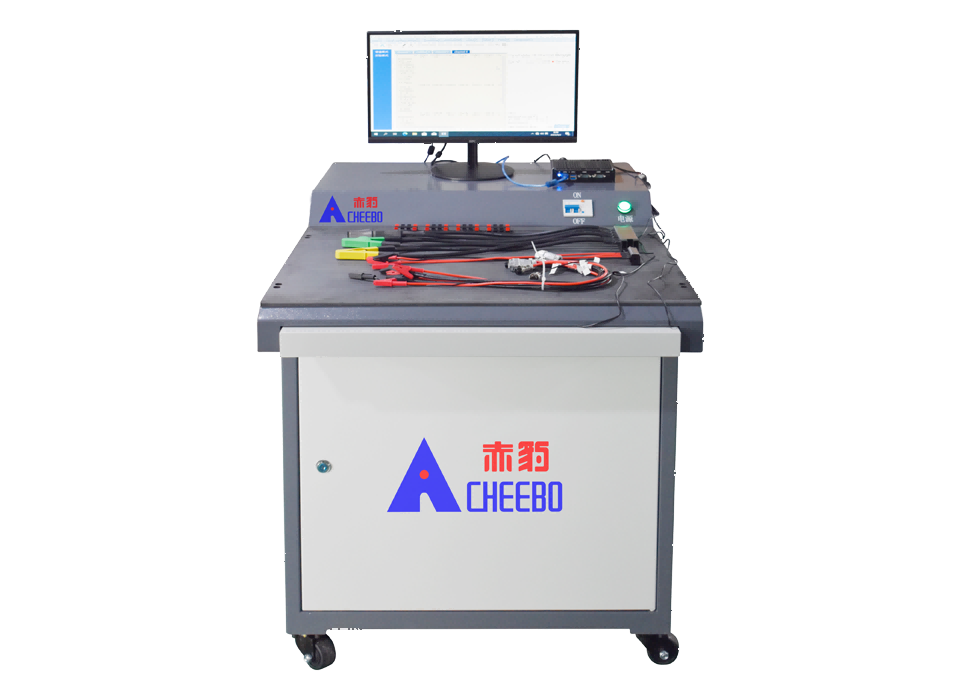

First Tier Brand Transistor Welding Power Supply

Taiwan Shangyin Rail Module

High Definition Touch Screen

Service Hotline

Service Hotline

E-mail:Cheebo@126.com

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry

Copyright © 2019 Shenzhen Cheebo Technology Co., Ltd All Rights Reserved. 粤ICP备19046161号

Website MapTechnical Support:SysxWeb