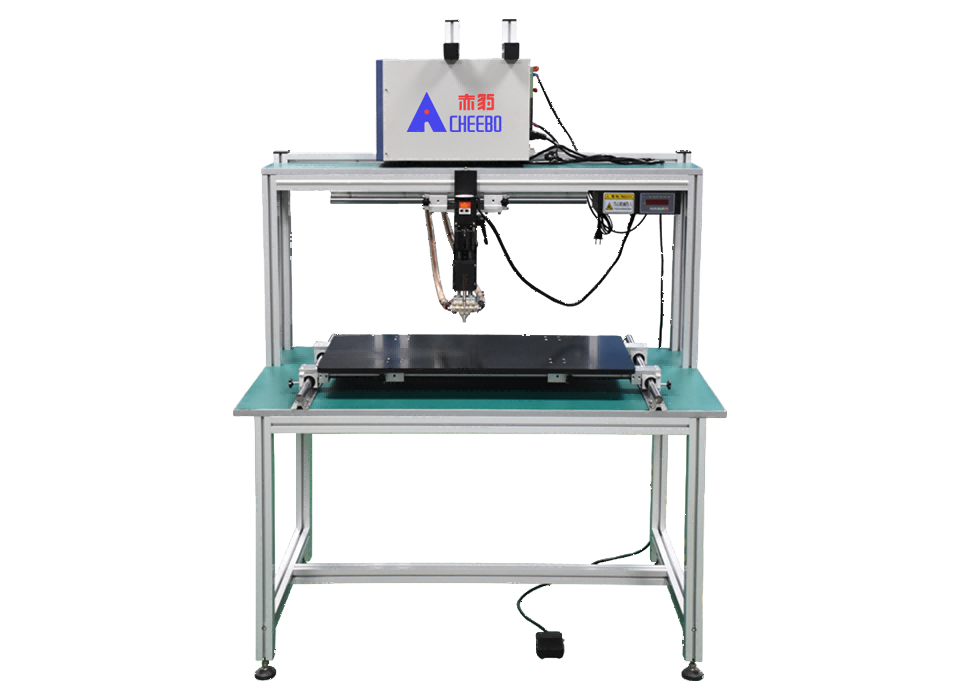

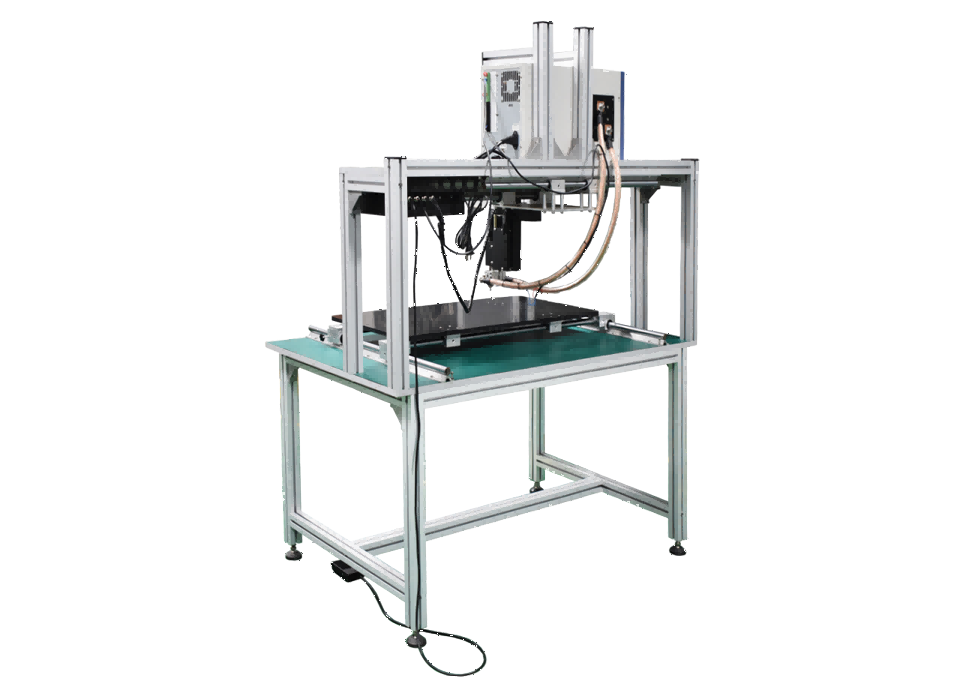

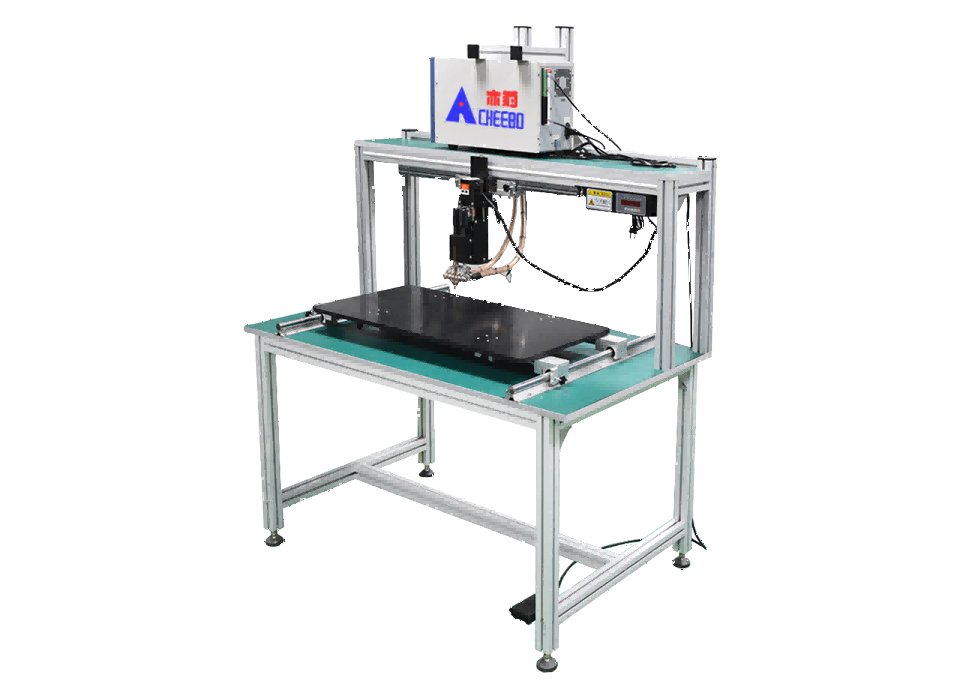

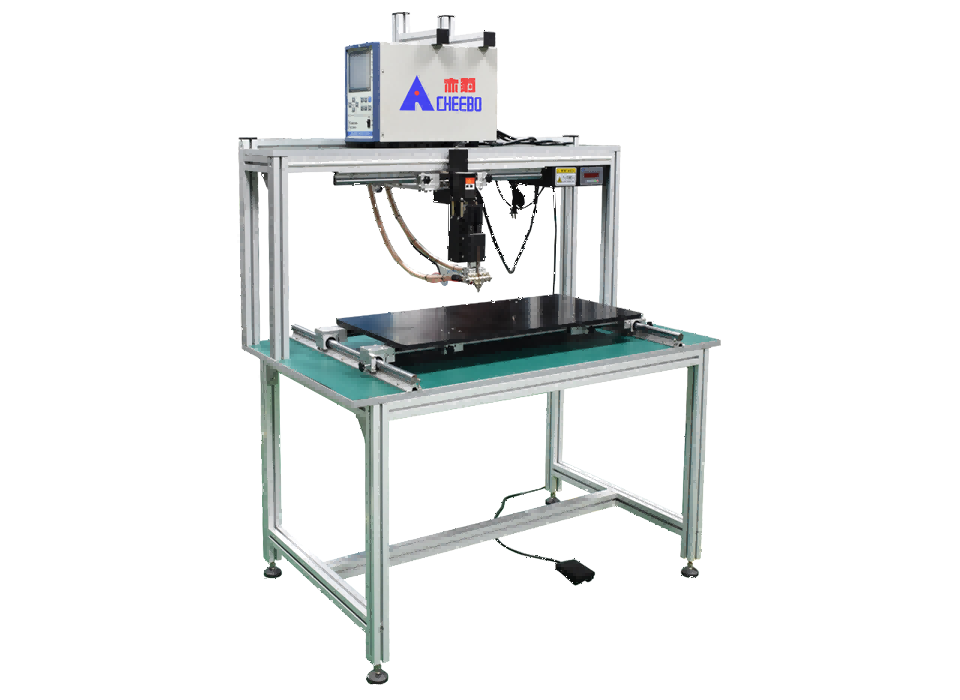

Guide Rail Gantry Spot Welding Machine CBLQ/DD

Product Feature Description:

1. Suitable For Spot Welding Processes Of Nickel Plating On Steel, Nickel Plating On Copper, And Pure Nickel Batteries

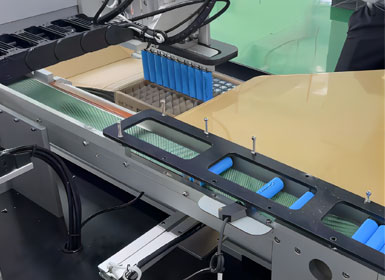

2. The Welding Head And Desktop Adopt A Rail Movable Type, Suitable For Welding Large Battery Packs, Saving Time And Effort

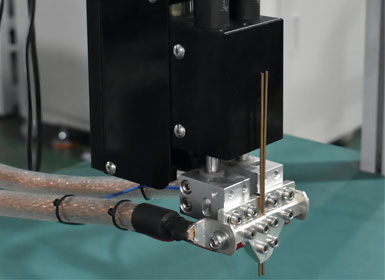

3. Independently Developed Precision Welding Machine Head, With Precise Adjustable Welding Pressure And Buffering Pressure Adjustment Mechanism, Can Effectively Reduce Damage To Battery Cells During Welding.

Standard Equipment Procurement

Equipment Customization And Upgrade Consultation

2. The Welding Head And Desktop Adopt A Rail Movable Type, Suitable For Welding Large Battery Packs, Saving Time And Effort

3. Independently Developed Precision Welding Machine Head, With Precise Adjustable Welding Pressure And Buffering Pressure Adjustment Mechanism, Can Effectively Reduce Damage To Battery Cells During Welding.

24H Service Hotline:19928807536

Main Features Of The Product

1、Using Gas Source Solenoid Valve Signal Control.

2、Configurable Semi Linkage Function.

3、The Height Of The Welding Head Of The Equipment Can Be Adjusted Up And Down, And The Minimum Height Of The Battery Should Not Be Less Than 50mm, And The Maximum Height Should Not Exceed 220mm (The Height Of The Raised Version Is 300mm). Welding Can Be Carried Out Within This Range.

4、The Detachable Design Of The Welding Head Clamp Can Be Used For Both Convex Spot Welding And Pointed Spot Welding.

5、High Quality Tempered Glass Is Used To Protect The Wear And Tear Of The Desktop, Making It Easy To Move During Welding.

6、Independently Developed Precision Welding Machine Head, With Precise Adjustable Welding Pressure And Buffering Pressure Adjustment Mechanism, Can Effectively Reduce Damage To Battery Cells During Welding.

7、By Using A Transistor Welding Power Supply, The Welding Output Waveform Can Be Improved, The Welding Ability Can Be Enhanced, And The Solder Joints Can Be Made Firm And Aesthetically Pleasing.

8、Adopting A 5.7-Inch High-Definition Lcd Screen, The Device's Various Parameter Adjustments Are Intuitive, Easy To Learn And Operate.

9、The Current Rises Rapidly, Achieving High-Quality Welding In A Short Period Of Time.

10、Microcomputer Technology Controls The Dynamic Real-Time Monitoring Of Welding Current, Voltage, Power, And Resistance Waveforms.

11、It Can Store Welding Parameters, With A Total Of 63 Sets Of Welding Parameters. It Can Weld Nickel Sheets Of Different Thicknesses And Can Be Easily Accessed, Making It Simple And Time-Saving.

12、The Output Current Has Polarity Switching Function, Effectively Eliminating The Polarity (Bipolar) That Occurs During The Welding Process.

13、The Design Adopts A Side Outlet Electrode, Which Is Easier To Assemble On Automated Equipment.

14、The Whole Machine Adopts Xingchen And Yadeke Execution Components.

15、Adopting Industrial Grade Circuit Design, The Circuit Is Safe, Reliable, And Has A Low Failure Rate.

16、The Device Has An Exquisite Appearance, Superior Structural Design, Compact And Reasonable Structure, Small Size And High Power.

17、The Whole Machine Adopts High-Quality Components

2、Configurable Semi Linkage Function.

3、The Height Of The Welding Head Of The Equipment Can Be Adjusted Up And Down, And The Minimum Height Of The Battery Should Not Be Less Than 50mm, And The Maximum Height Should Not Exceed 220mm (The Height Of The Raised Version Is 300mm). Welding Can Be Carried Out Within This Range.

4、The Detachable Design Of The Welding Head Clamp Can Be Used For Both Convex Spot Welding And Pointed Spot Welding.

5、High Quality Tempered Glass Is Used To Protect The Wear And Tear Of The Desktop, Making It Easy To Move During Welding.

6、Independently Developed Precision Welding Machine Head, With Precise Adjustable Welding Pressure And Buffering Pressure Adjustment Mechanism, Can Effectively Reduce Damage To Battery Cells During Welding.

7、By Using A Transistor Welding Power Supply, The Welding Output Waveform Can Be Improved, The Welding Ability Can Be Enhanced, And The Solder Joints Can Be Made Firm And Aesthetically Pleasing.

8、Adopting A 5.7-Inch High-Definition Lcd Screen, The Device's Various Parameter Adjustments Are Intuitive, Easy To Learn And Operate.

9、The Current Rises Rapidly, Achieving High-Quality Welding In A Short Period Of Time.

10、Microcomputer Technology Controls The Dynamic Real-Time Monitoring Of Welding Current, Voltage, Power, And Resistance Waveforms.

11、It Can Store Welding Parameters, With A Total Of 63 Sets Of Welding Parameters. It Can Weld Nickel Sheets Of Different Thicknesses And Can Be Easily Accessed, Making It Simple And Time-Saving.

12、The Output Current Has Polarity Switching Function, Effectively Eliminating The Polarity (Bipolar) That Occurs During The Welding Process.

13、The Design Adopts A Side Outlet Electrode, Which Is Easier To Assemble On Automated Equipment.

14、The Whole Machine Adopts Xingchen And Yadeke Execution Components.

15、Adopting Industrial Grade Circuit Design, The Circuit Is Safe, Reliable, And Has A Low Failure Rate.

16、The Device Has An Exquisite Appearance, Superior Structural Design, Compact And Reasonable Structure, Small Size And High Power.

17、The Whole Machine Adopts High-Quality Components

Product Technical Parameters

| Welding Method | Single Sided Double Point Balanced Welding | Desktop And Welding Head Height | 220MM (Maximum Spacing) Adjustable |

| Welding Thickness | 0.04-0.3mm(Depending On The Selected Power Supply) | Welding Power Source | Transistor, Dual Segment Multi Pulse (Optional) |

| Power Supply Current | Depending On The Selected Power Supply | Welding Speed | 200P/M (Maximum) |

| Spot Welding | Convex Or Pointed Point | Welding Pressure | 5KG/F (Adjustable) |

| XY Axial Travel | 750*350 (Manual Sliding Of Guide Rail) | External Dimensions | 700*1200*1450mm |

| Drive Mode | Electric, Pneumatic (Optional) | Equipment Weight | 70KG |

| Power Specifications | Single-Phase 220V 50/60HZ 2.8KW | Application Scenarios | Sample Making And Small-Scale Production |

Product Details Display

Pneumatic Precision Welding Machine Head

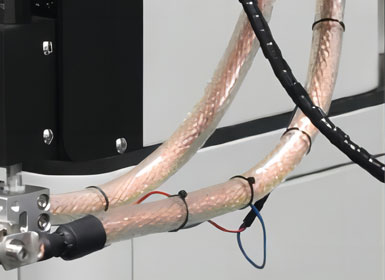

Pure Purple Copper Thick Cable

Transistor Power Supply

Adjustable Welding Head Mechanism

Service Hotline

Service Hotline

E-mail:Cheebo@126.com

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Shenzhen Headquarters: Block A, 3rd Floor, Building 1, Houhai Xufa Technology Park, No. 8 Zhenxing Road, Loucun, Xinhu Community, Guangming New District, Shenzhen, Guangdong Province, China

Zhejiang Office: No. 45, 6th Street, Wuzhong South Road, Changcheng Economic Development Zone, Yongkang City, Jinhua City, Zhejiang Province

Message Inquiry

Message Inquiry

Copyright © 2019 Shenzhen Cheebo Technology Co., Ltd All Rights Reserved. 粤ICP备19046161号

Website MapTechnical Support:SysxWeb